Plast-Box

Ukraine

The Company

Plast-Box Ukraine

The main activity direction of the enterprise is the production of containers of different volumes, shapes and colors with plastic or metal handles. The company attaches great importance to the development of new solutions in the design and decoration of containers and packaging. Customers of the company have a wide range of round, oval and rectangular containers of capacity from 0.5to 33l, which allow flexible solution of the problems of production economy, storage and transportation, successful brand promotion by creating unforgettable image.

“Plast-Box Ukraine” products are widely used in many industries. Containers are used for the needs of the food market, including fish, dairy products, ketchup, mayonnaise, fruit and vegetable jam, and canned goods. The company also specializes in the manufacture of packaging for the chemical market, in particular for paint and varnish materials and construction chemistry.

Another area of activity of the company is the production of boxes. Boxes “Plast-Box Ukraine” are widely used for transportation and storage of vegetables and fruits, meat and dairy products, fish,and bakery products. Sophisticated and well-thought-out box design, based on decades of production experience, and carefully selected materials ensure their reliability and long-term exploitation. Such containersare are suitable for deep freezing (-40° C) and allow sanitary treatment due to high material resistance to aggressive environments.

Technology

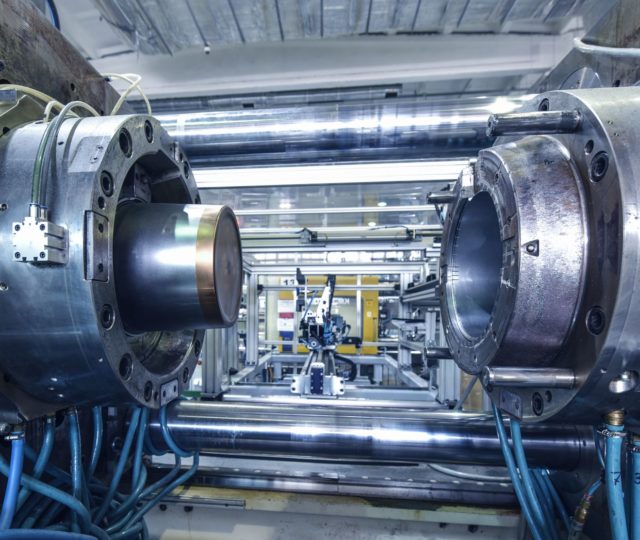

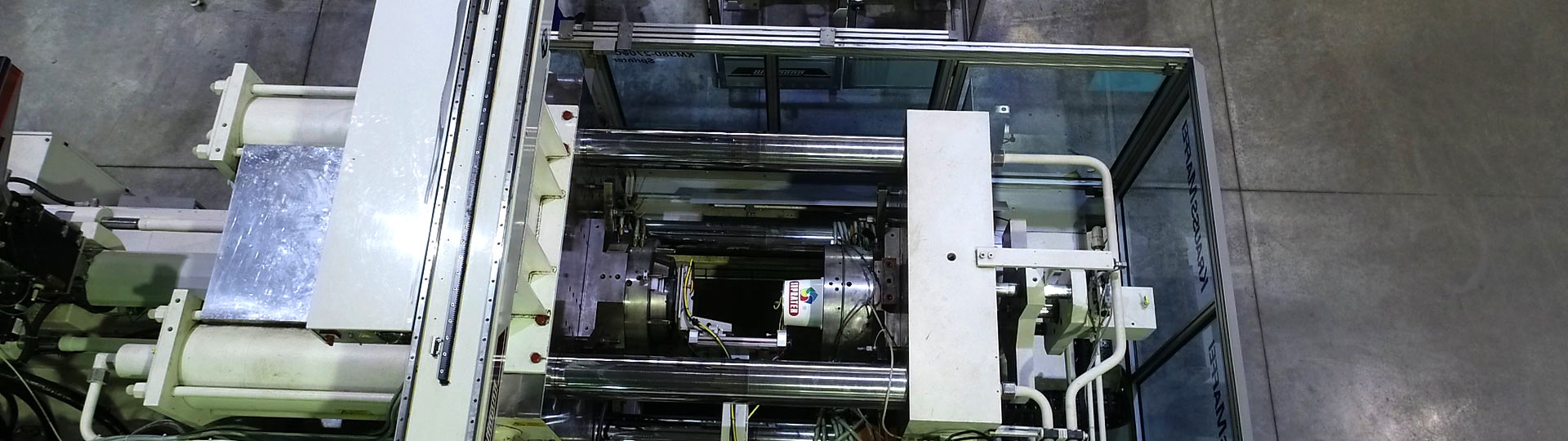

Modern technologies

The diversity of the assortment offered by Plast-Box Ukraine allows each customer to find the best packaging for his goods.

According to the clients’ demand the buckets can be equipped with plastic or metal handles. The company manufactures containers which, due to their design features (special shape of the bottom, external hinge, the presence of a “shaker” lock in the container sealing unit, a special form of centering petals on the lid, etc.), are the most suitable for mixing paint and varnish materials on gyroscopic and vibroshakers.

Packages of the same capacity may differ in individual size: the bottom and top diameter, height, the construction of the lid or side cap, which allows you to pick up the container, based on your own needs, for example, the settings of the technological line.

Recognition of a company’s product on the market is very important. Manufacturing companies prefer their product to be packed in packaging not only of a certain form, but also had an individual decorative design. This can be done in several ways. One of them is the ability to make a bucket, a lid or plastic handle of any color.

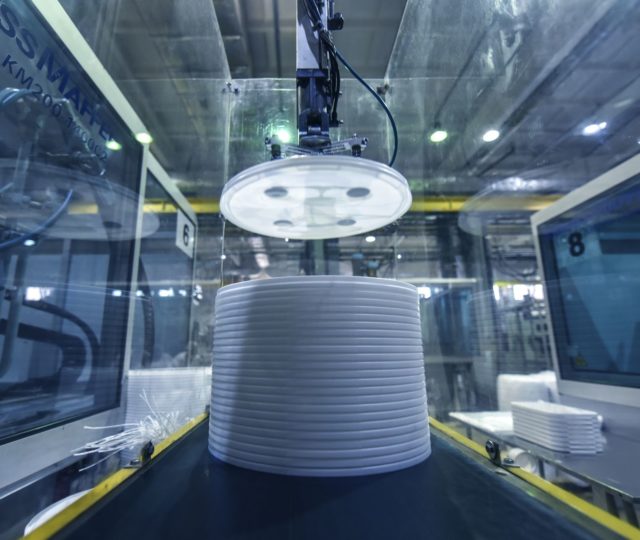

We offer an existing standard colours, as well as we can choose a special color that will significantly distinguish the product. Another way of decoration is by using the IML technology (In-Mold-Labeling technology). This method of decoration is carried out at the request of the customer by packing pre-printed labels into the products at the time of their formation.

IML technology

To give you the opportunity to understand the possible areas of using products with IML-labels better, we will briefly list their main benefits:

- the label and packaging look like organic whole, which increases the external attractiveness of the goods;

- products with IML labels have increased resistance to external mechanical and chemical influences; the soldered labels are damp-proof and hygienic, as well as resistant to temperature fluctuations. So, this is the best solution for decorating plastic containers for frozen and cooled products.

- high-quality printing is used for the production of labels, therefore the product has clear graphics and photorealistic images on the packaging, which allows you to highlight the goods on the shelves of stores;

- decorating with IML allows you to create a wide range of design solutions for plastic products, using a variety of combinations of foundations, paints and varnishes;

- additional protection against counterfeiters is automatically provided, as a rule, fairly large manufacturers, who will not participate in pirated production, have IML-technology;

- the cost of labeling is reduced, as this operation is combined with the process of making the package;

- the packaging is completely recycled (because the label and packaging are made of the same material), which helps to protect the environment;

- it is possible to use higher (10-20%) speed of packaging of the product, since the label has a strong adhesion to the surface, which, in turn, reduces the risk of damaging;

- Internal firmware accounting for finished packaging is facilitated (if all containers are marked and signed, it’s more difficult to mix them than “nameless” containers).

Specification